|

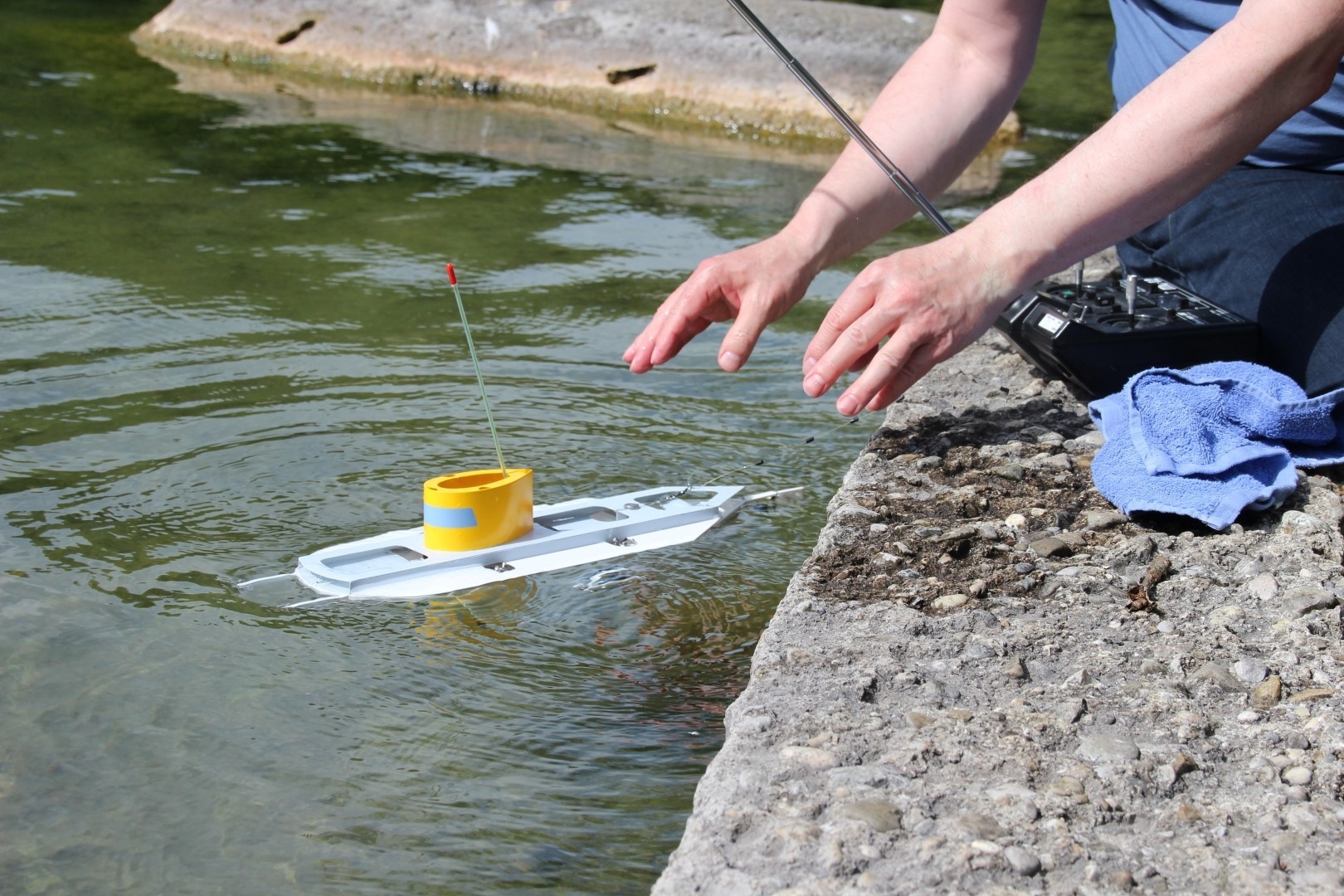

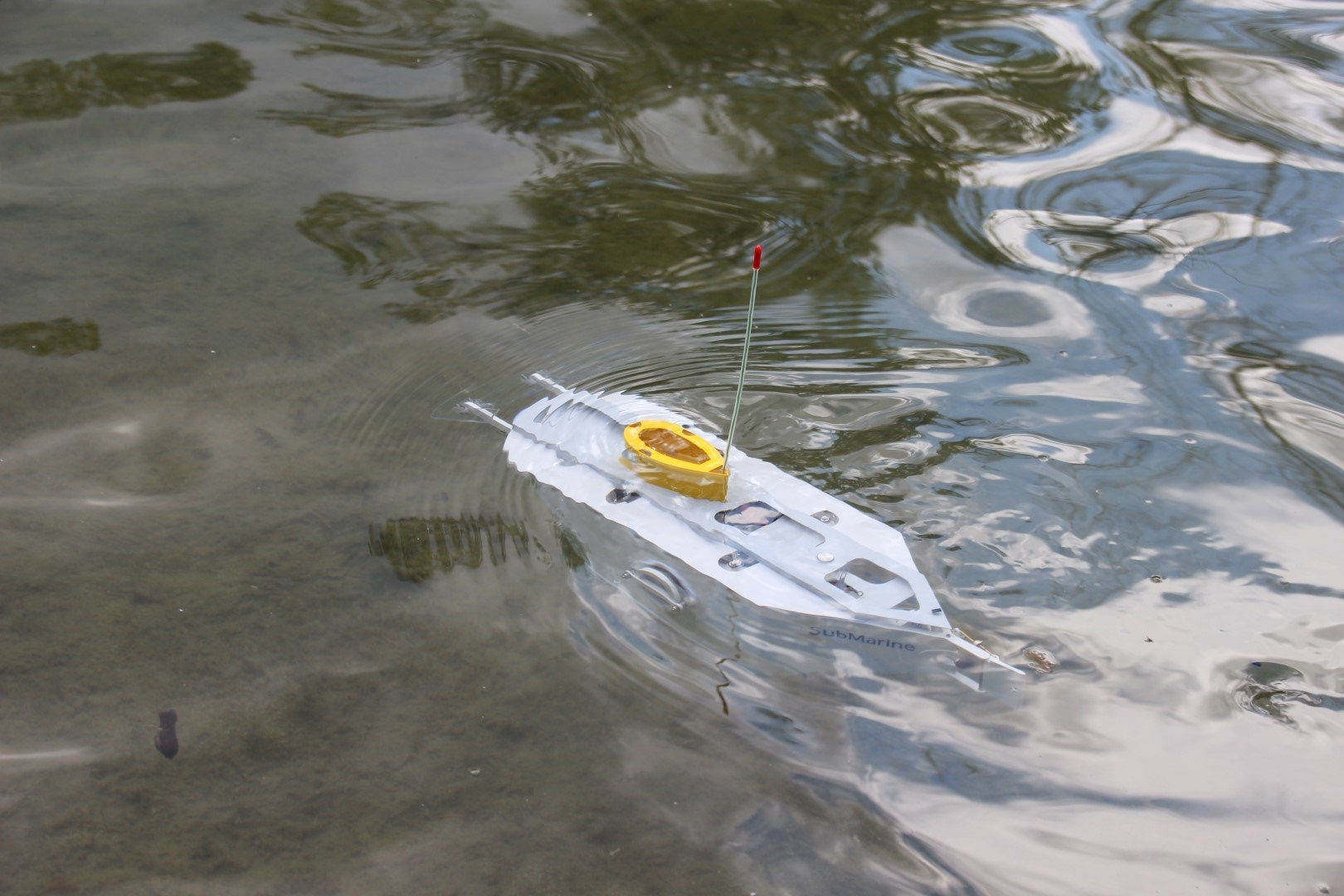

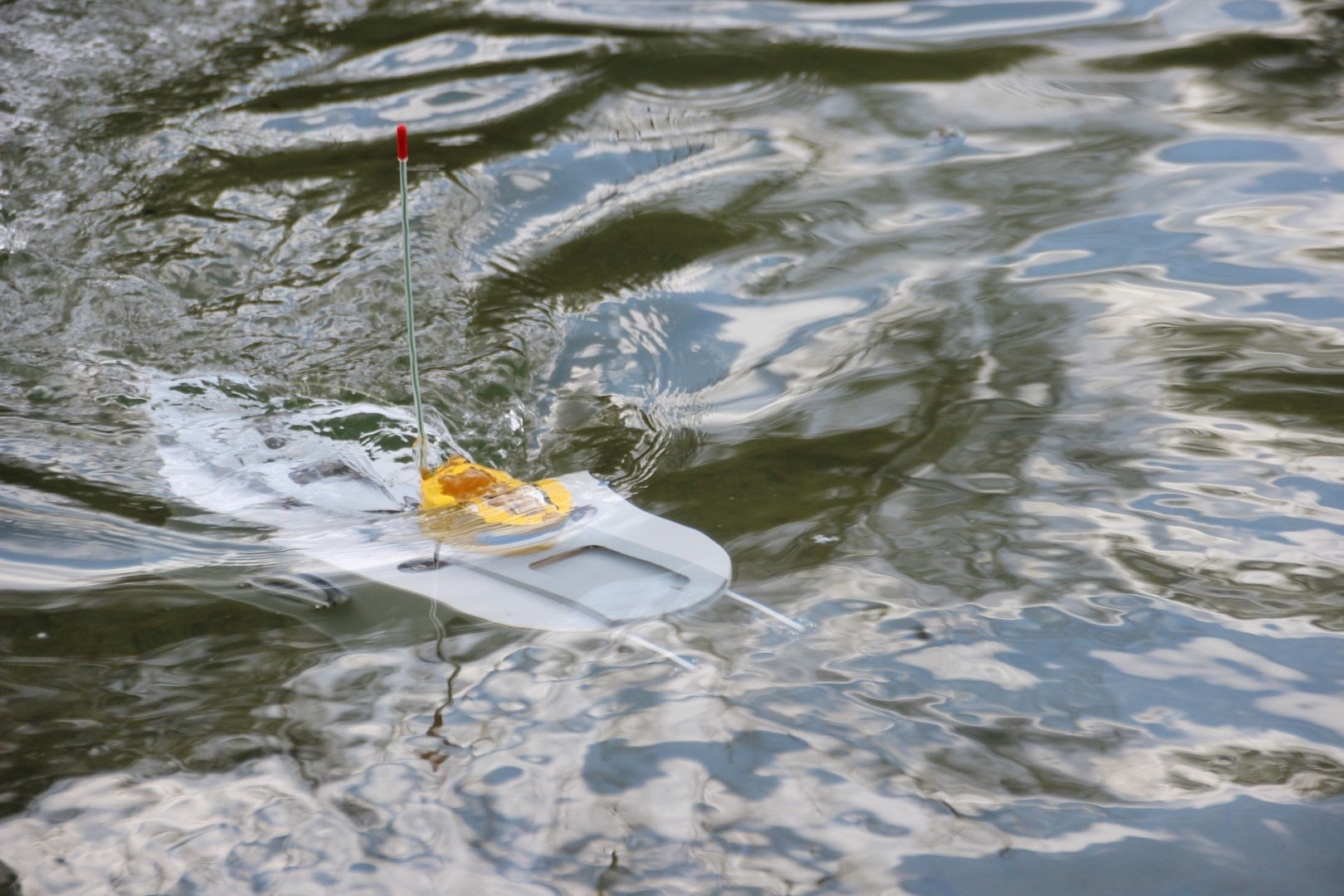

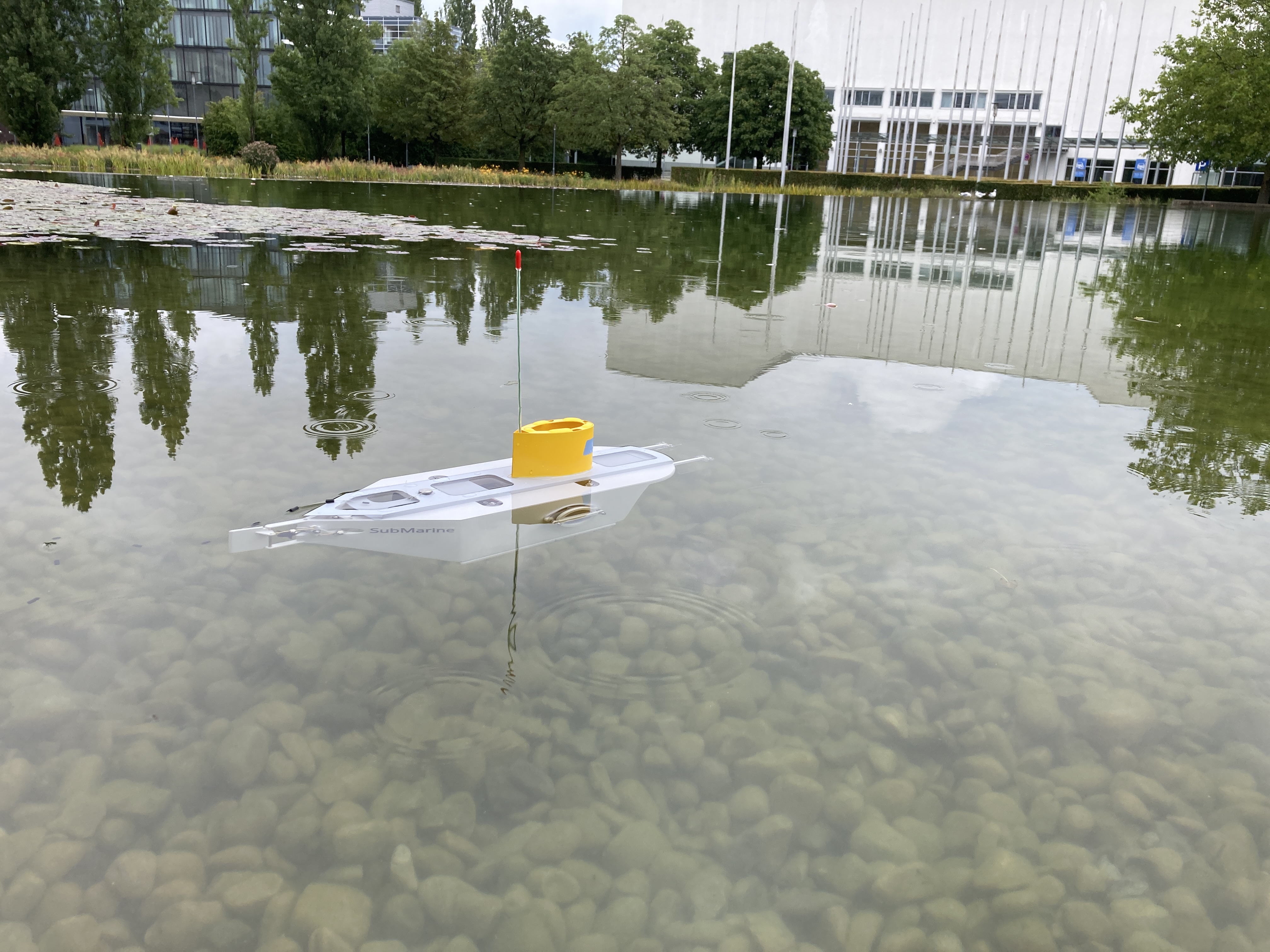

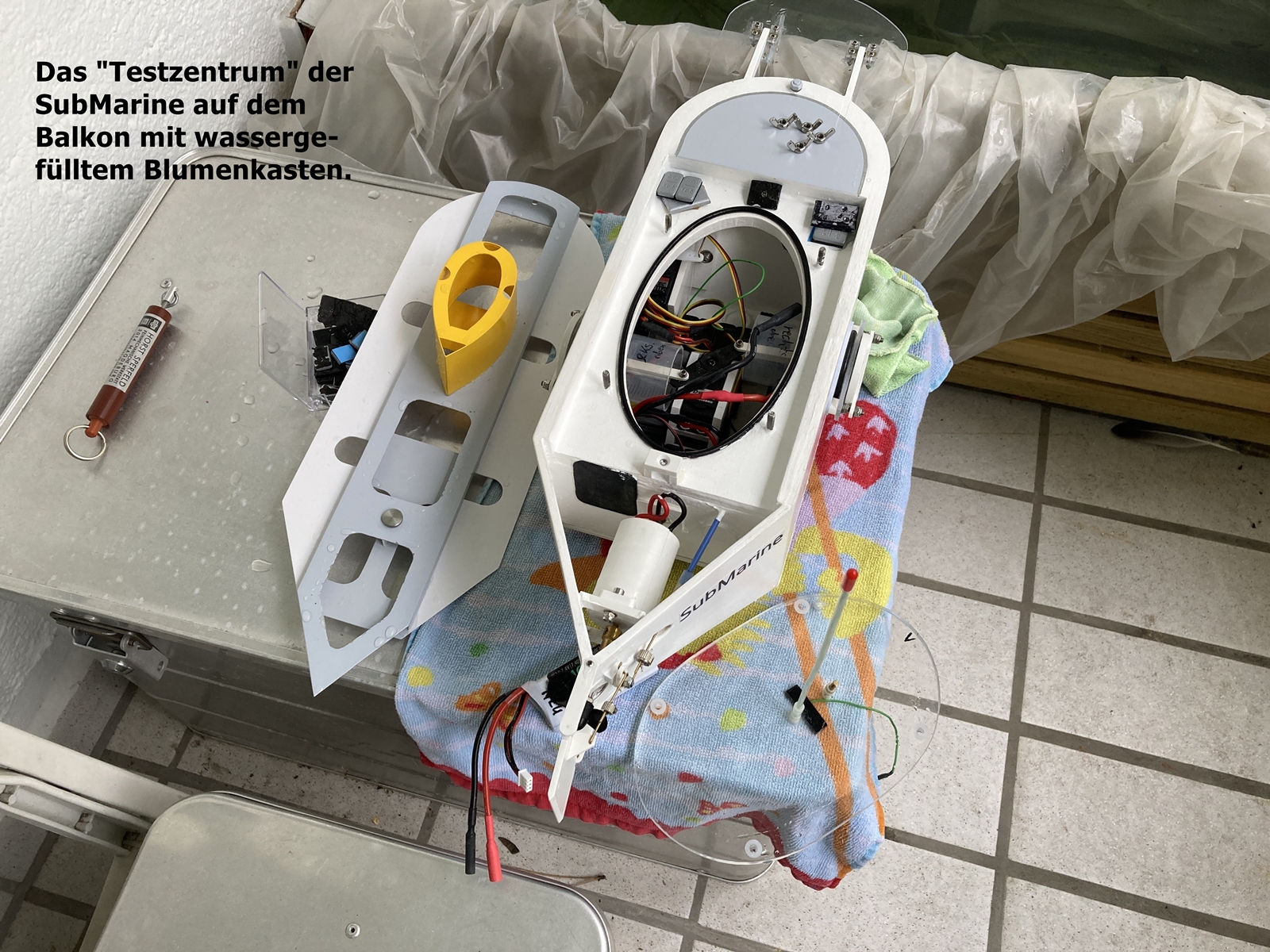

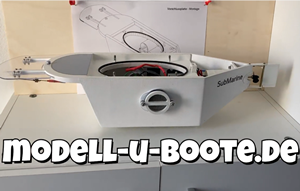

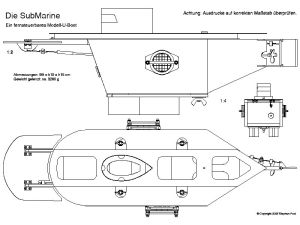

The SubMarine was designed based on the original manned research submersibles and, as I always aim for, was intended to be as simple in construction as possible. Most of the time, I find along the way that it's not that simple after all.

A submarine is a demanding project. It must be watertight, pressure-resistant, and reliable, exhibit good dynamic handling characteristics, and then there are my personal requirements for simple construction, good accessibility, ease of maintenance, safety, practical handling, and low weight.

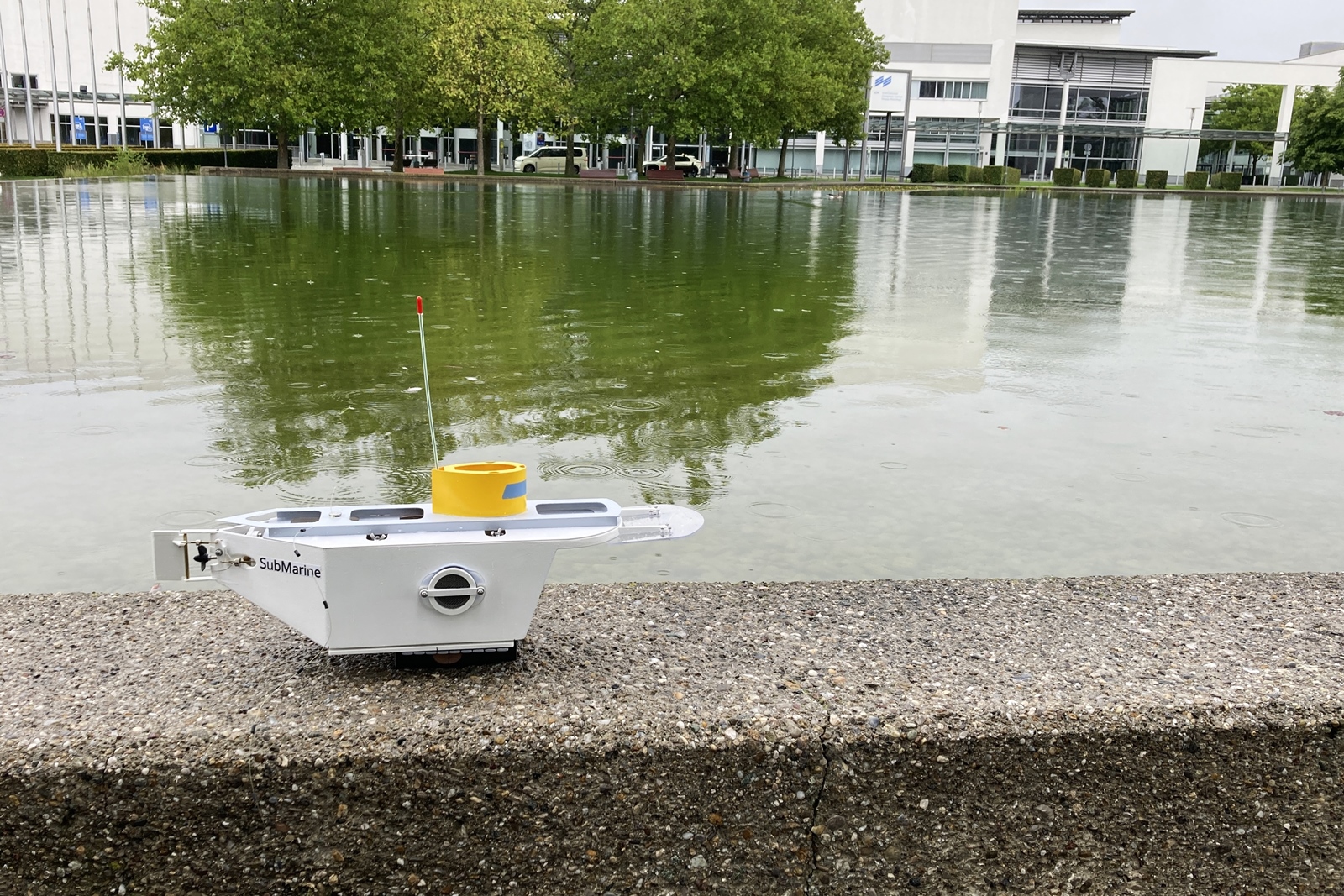

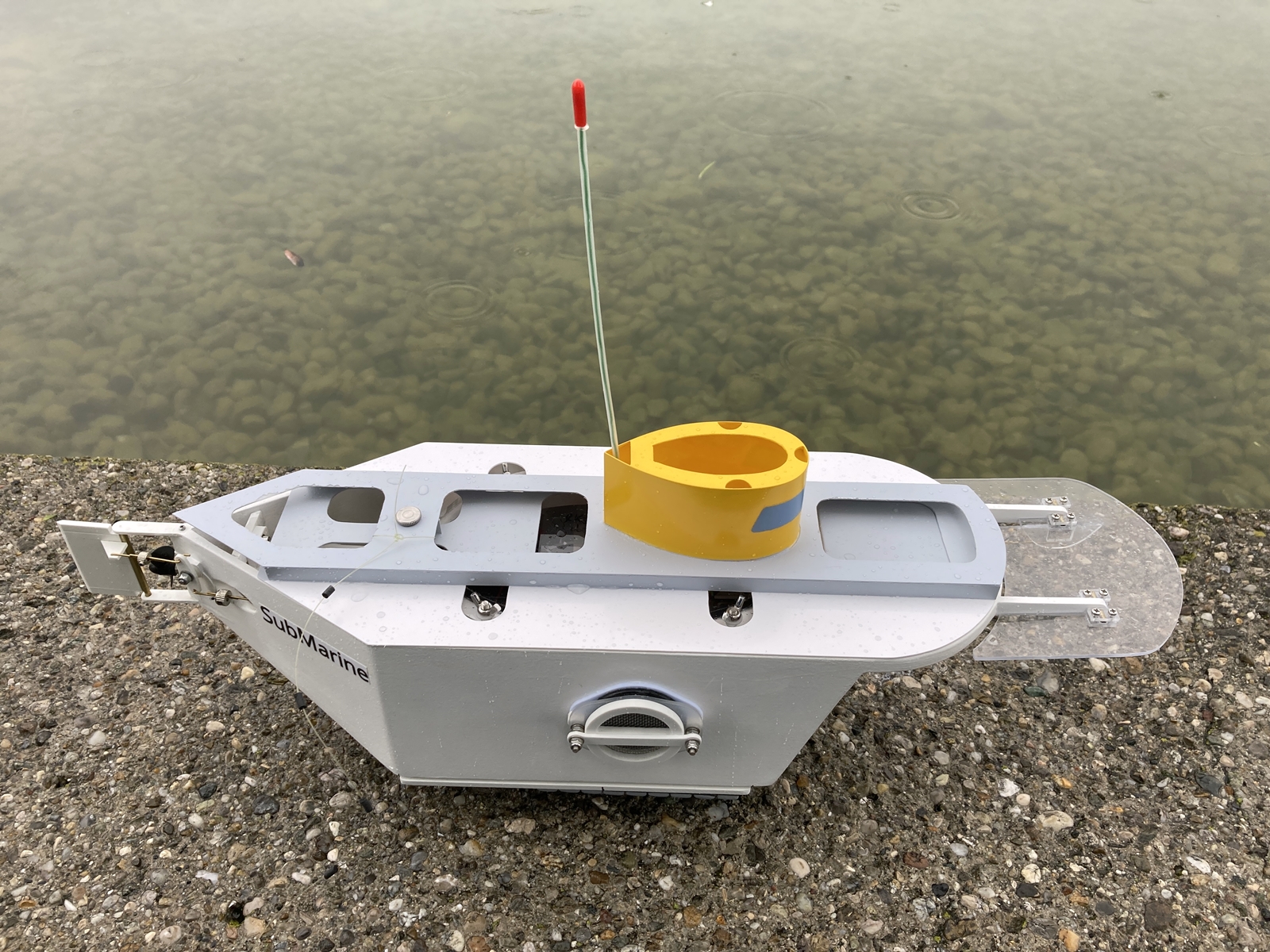

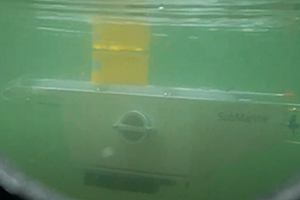

So the SubMarine, for which I honestly couldn't think of a more fitting name, was eventually built from wood and plastic sheets. Specifically, it was frameless, but made from 10 mm plywood sheets – at least for the pressure hull. I'll say it right away:

today I would build at least the pressure hull from polycarbonate or rigid PVC sheets, because it became clear relatively quickly that my wood varnish hadn't been very effective to protect the plywood sheets from the water.

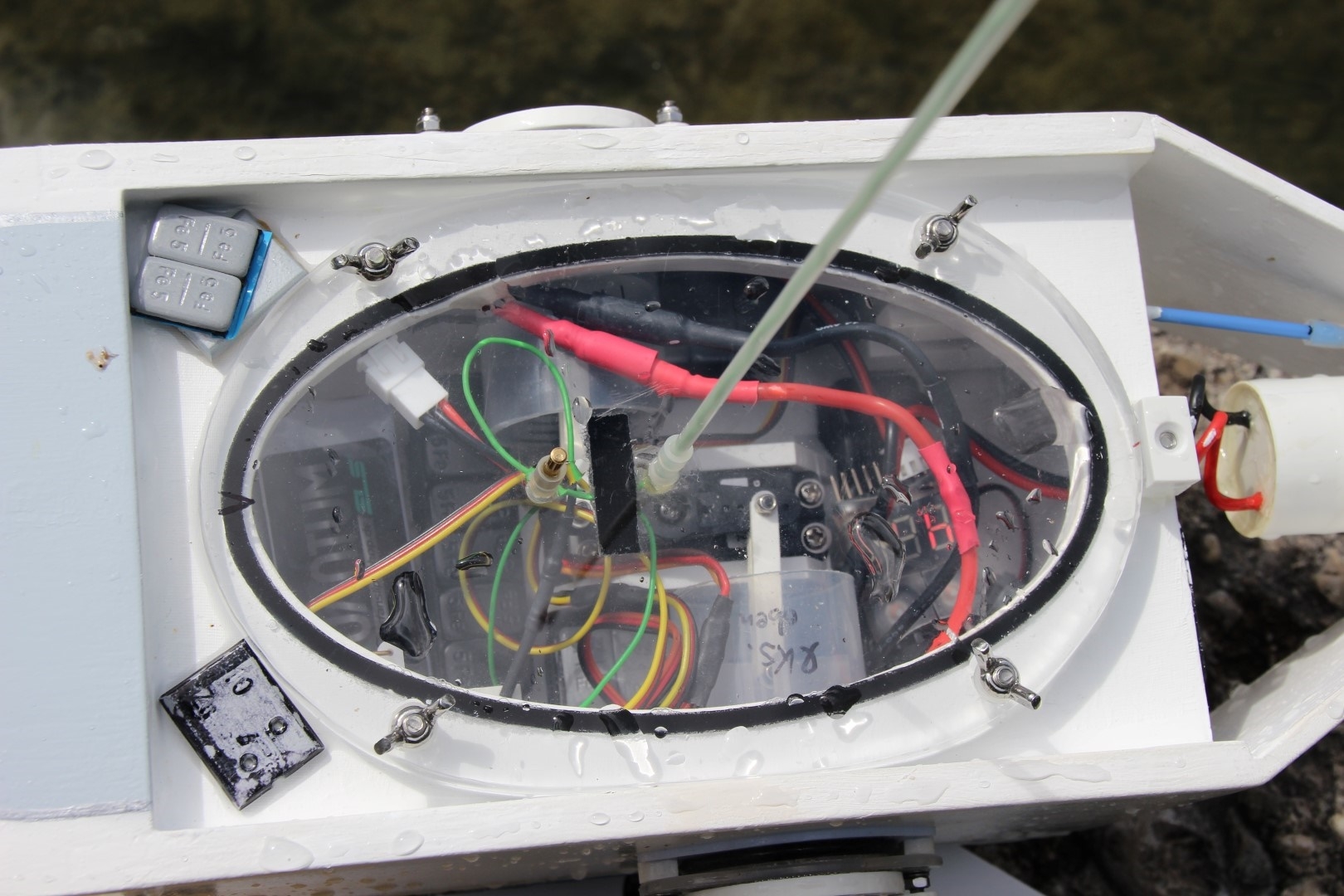

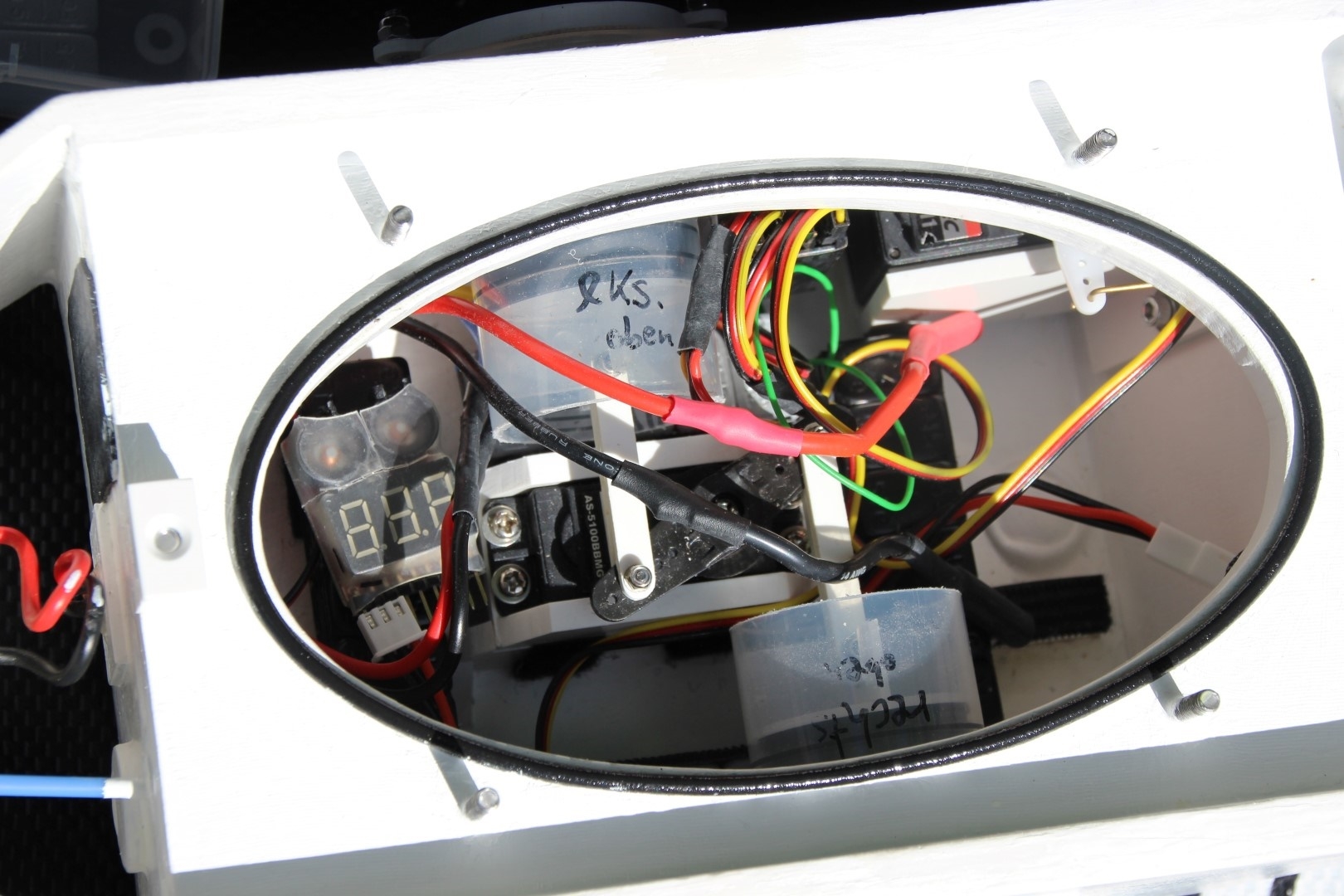

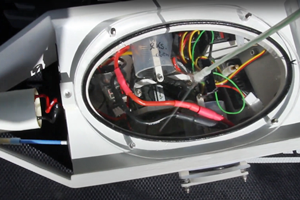

The diving system consists of two modified medical syringes, which are jointly controlled by a centrally located servo. This system implements changes in displacement virtually instantaneously, i.e., without any waiting time.

The two syringes are not glued in, but are guided into the pressure body in O-rings, so that they can be easily replaced.

The two rudder servos are each attached to the pressure hull with only one screw.

The pressure hull of the SubMarine can be completely hollowed out in a few minutes, with the exception of the diving servo mount, should you wish to do so.

The control linkages are sealed via O-rings, which are pressed onto the linkage by a "too small" silicone hose.

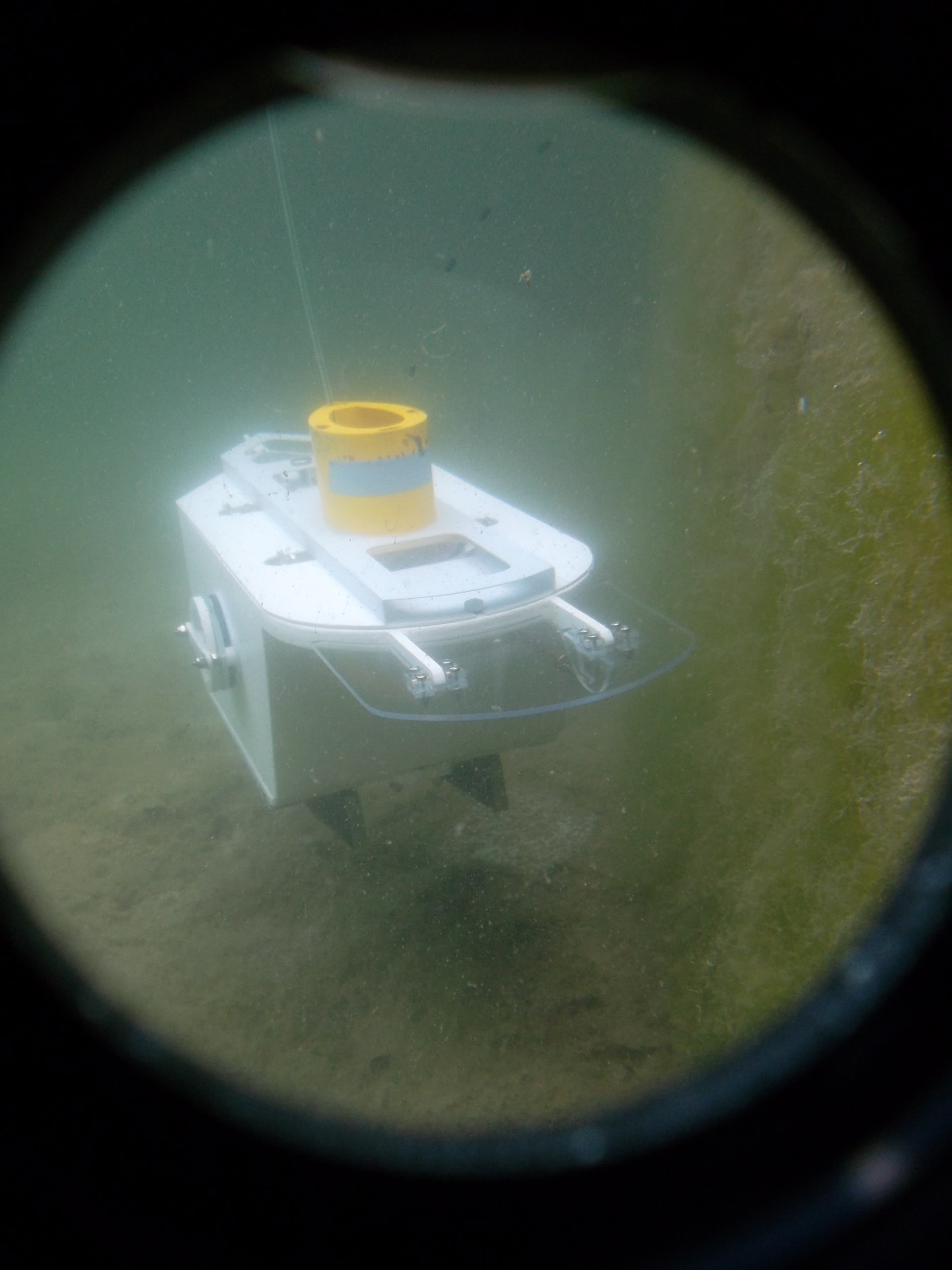

The ballast is mostly attached to a plastic plate mounted under the boat and can be moved forwards and backwards to adjust the center of gravity. A major part of this ballast consists of two hammerheads. The fact that it can be removed significantly simplifies some assembly work and can also be advantageous during transport.

I wanted to avoid lead because of its toxicity. The hammerheads are made of steel and offer compact weight in a suitable size and also a usable streamlined shape.

The external motor is sealed to the shaft with a Teflon plate.

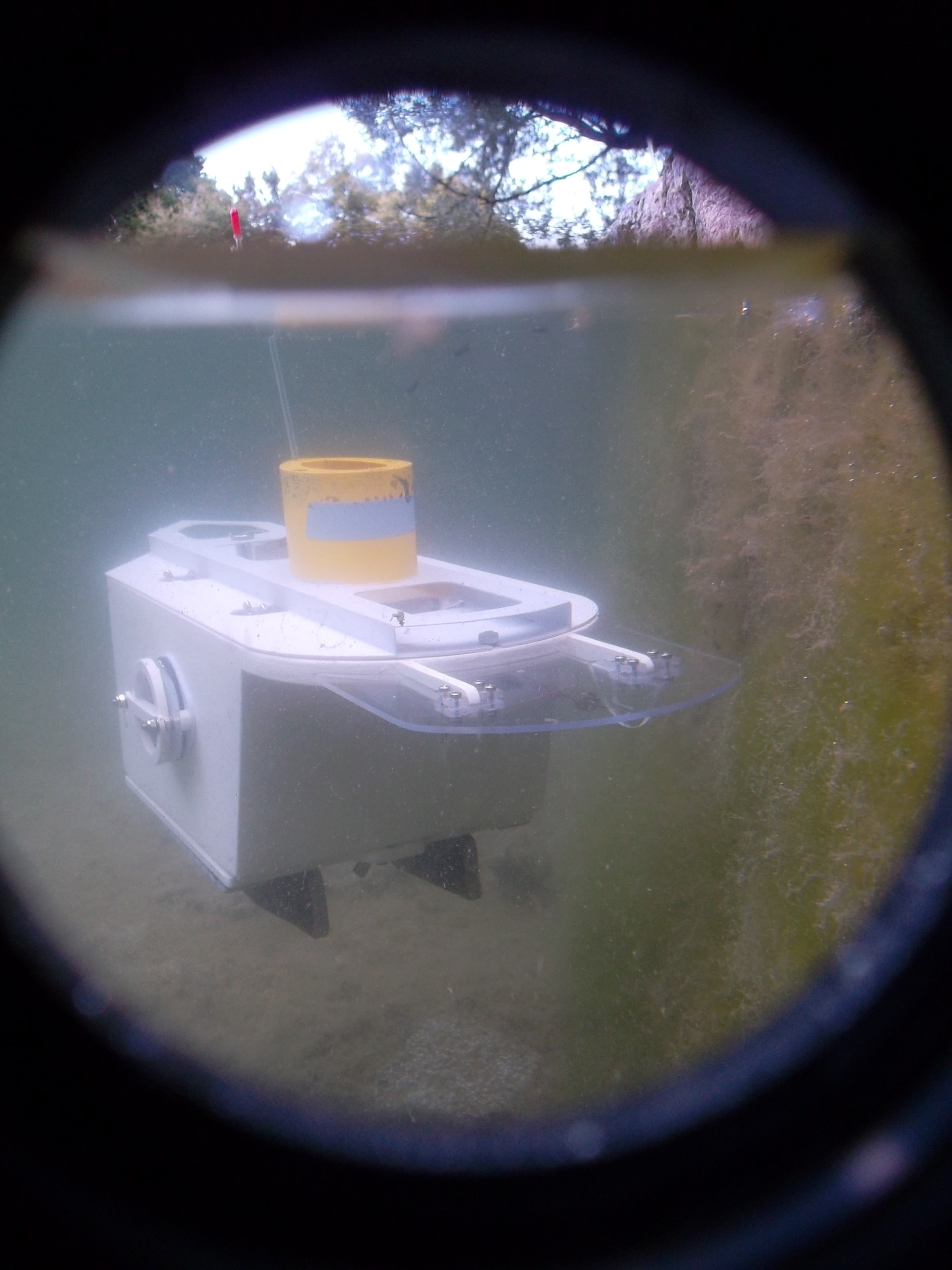

The antenna can be positioned vertically or horizontally. To do this, it is simply folded down and guided into the intermediate deck area.

Despite the relatively small size of the SubMarine and the use of standard servos, there is still room for additional features, such as a camera.

What's also interesting about the SubMarine is its form factor, which allows for a clear and uncluttered interior while simultaneously resulting in a compact and robust appearance. And all this without significantly compromising its handling characteristics.

A free construction plan including 3D data (STL and STEP) is available for this model submarine.

|

|